RILSAMID®

< See all materials

Applications

- Aerospace

- Automobile and truck

- Building

- Defense, security, protection

- Electric and electronic

- Fluids transportation

- Industry and tools

Transformation

- Extrusion

- Injection

Normes

- Food contact – FDA

Description

Technical datasheets

Contact

Rilsamid® PA12 is particulary well suited for different processing technologies: extrusion, injection, blow-moulding processes, etc…

Due to versatility and outstanding properties, Rilsamid® meets the quality requirements of a wide range of markets. Arkema’s PA12 products are used in automotive, electric and electronic, industrial and sport applications.

Features

- Very low density (The lowest density of any engineering polymer)

- High impact strength, even at low temperatures

- Very low moisture pick-up and good dimensional stability

- Wide range of customizable flexibility levels

- Excellent abrasion resistance and low friction coefficient

- Long term performance

- Excellent chemical resistance

- Good barrier properties

- Good weathering resistance

- Easy processing: extrusion, injection moulding, and roto-moulding among others

Applications

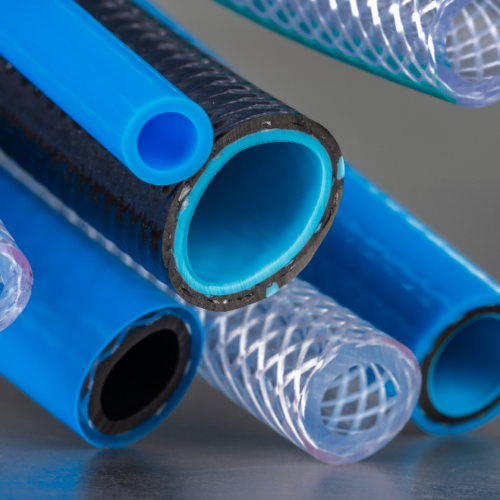

- Petrol / fuel hoses, steam pipes, flexible connections, cable ties and clips

- Fuel lines, convoluted in-tank fuel tubing, fuel line quick connectors

- Hydraulic flexible pipes: brakes, suspension, clutch

- Pneumatic pipes and pneumatic servo brake systems

- Compressed air braking systems for heavy goods vehicles

- Metal tube coating (metallic brake lines / metallic fuel lines)