PRE ELEC

Applications

- Automobile and truck

- Building

- Defense, security, protection

- Electric and electronic

- Fluids transportation

- Hobbies

- Industry and tools

- Office equipment

- Packaging

Transformation

- 3D extrusion

- Bottling

- Extrusion

- Injection

- Termoforming

Normes

- ATEX (explosion-proof)

- Food contact – FDA

Description

Technical datasheets

Contact

Create a safe society with functional plastics

Premix Oy is an European market leader and global forerunner in electrically conductive plastics. The compounds are based on PP, PE, PS, ABS, PC, PC/ABS, PA, PBT, TPU and TPE. The special expertise is based on carbon black, carbon fiber & IDP know-how. The expertise lies in formulation and production of functional plastic materials. Premix’s materials are more than just traditional plastics -they play an active role int he product or process they are integrated.

Premix offers a comprehensive portfolio of electrically conductive PRE-ELEC® plastic compounds and concentrates static dissipative PRE-ELEC® ESD compounds. There are many creative ways to utilize conductive plastics like metal remplacement, energy storage, level detection, heating elements, air-purification or preventing electrostatic attraction (ESA).

Premix’s electrically conductive material solutions provides permanent surface resistance and volume resistivity in the range of 10 Ω to 10 11 Ω. Due to the nature of carbon black, reaching a dissipative surface resistance levels above 105 Ω is a challenging task.

Premix has successfully overcome this challenge with special resistance control technology and offers static dissipative PRE-ELEC® compounds between 10 E 5 Ω and 10 E 8 Ω.

Controlling static electricity

- Electronics protection

- Fire/explosion safety with flammable chemicals (ATEX)

- Sensors : Detection of liquid, breakage and precise dosage

- Electrostatic painting of plastic items

- Conductor

- Dust attraction control

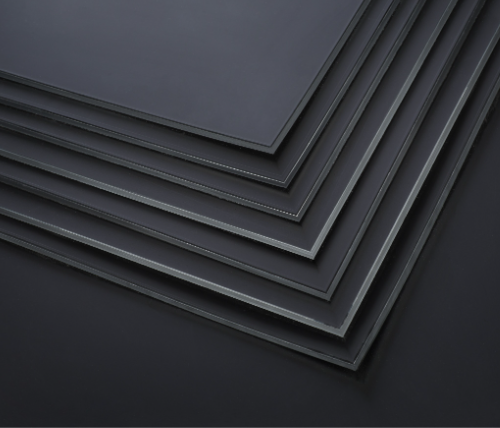

Films

Range of compounds based on PEBD for film production permanent heatsink (in middle layer of multi-film layer)

Medias and documents

- Controlling static electricity: Mastering static electricity with electrically conductive plastics

- Premix and electrically conductive plastics specific prosessing- and technical data available on Data center

To remember

PRE-ELEC® allows you to:

-

- Control static electricity discharges in electronic or explosive environments

- Detect fluid levels

- Replace metal

- Having dust-free products

- Allow electrostatic painting

Notre contact

Soler Oriol

Responsable desarrollo comercial y referente técnico Iberia

+ 34 674 367 814

osoler@amp.fr